The global peptide therapeutics market, projected to reach $75 billion by 2028, faces a critical sustainability inflection point as pharmaceutical packaging generates over 300,000 tons of plastic waste annually, with complex peptide vials, syringes, and cold-chain materials contributing disproportionately to the industry’s environmental footprint. With 68% of healthcare consumers now considering environmental impact in treatment decisions and regulatory bodies across 45 countries implementing extended producer responsibility (EPR) mandates, sustainable packaging innovation has evolved from a niche consideration to a $2.5 billion market opportunity and strategic imperative.

This comprehensive analysis examines how peptide manufacturers are pioneering next-generation sustainable materials and circular design principles to achieve 40-60% reductions in packaging carbon footprint, 50-70% decreases in single-use plastic waste, and significant cost savings while maintaining the stringent sterility, stability, and patient safety requirements essential for these high-value biopharmaceuticals.

The Sustainability Imperative in Peptide Pharmaceutical Packaging

Traditional peptide packaging presents a complex sustainability challenge that demands innovative solutions balancing product protection with planetary health.

The Environmental Burden of Conventional Packaging

Current packaging systems create significant ecological impacts:

- Material Intensity: Multi-layer plastic blisters, glass vials, and aluminum seals.

- Cold Chain Waste: Single-use expanded polystyrene (EPS) and polyurethane foam shippers.

- Low Recycling Rates: <5% of pharmaceutical packaging recycled due to contamination concerns.

- Carbon Emissions: Packaging contributes 20-30% of peptide product carbon footprint.

Market Drivers for Sustainable Transformation

Multiple forces accelerating the shift toward sustainable packaging:

- Regulatory Pressure: EU Packaging and Packaging Waste Directive, US EPA mandates.

- Investor Scrutiny: $35+ trillion in ESG-focused assets demanding sustainable practices.

- Patient Expectations: 65% preference for environmentally responsible packaging.

- Cost Optimization: 20-40% savings through material reduction and circular models.

“Sustainable packaging for peptide therapeutics isn’t merely an environmental initiative—it’s a fundamental redesign of how we protect and deliver these vital medicines. By reimagining materials, minimizing waste, and embracing circular principles, we can significantly reduce our environmental impact while enhancing patient experience and creating substantial business value.” — Dr. Sarah Chen, Director of Sustainable Packaging, Global Pharma Innovations.

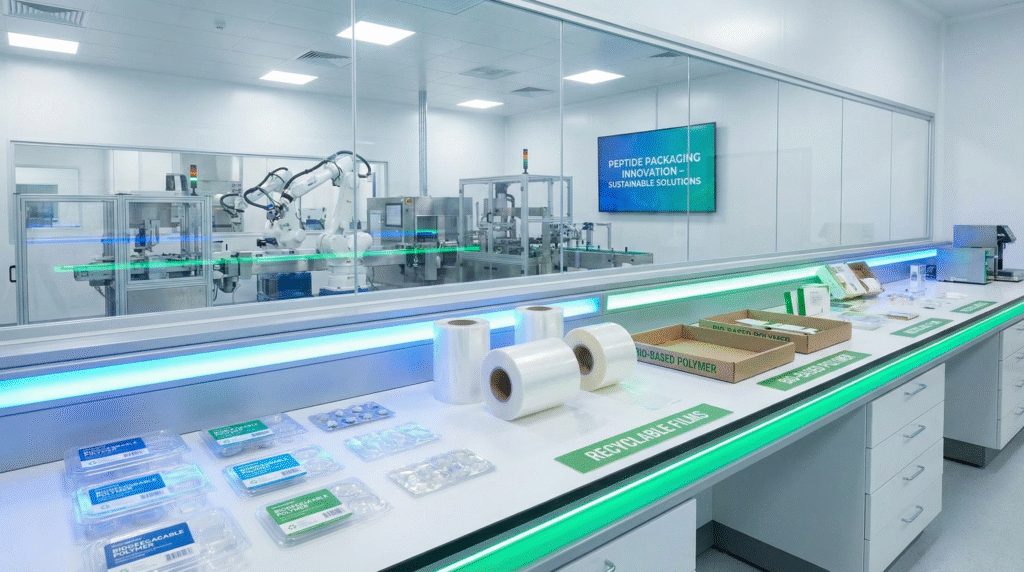

Innovative Sustainable Materials for Peptide Packaging.

Next-generation materials are replacing traditional plastics and composites with environmentally preferable alternatives that maintain performance.

Bio-based and Biodegradable Polymers

Renewable materials with reduced environmental impact:

| Material Class | Key Properties | Peptide Applications | Environmental Benefit |

|---|---|---|---|

| Polylactic Acid (PLA) | High clarity, good barrier, compostable | Blister packs, trays | 60-70% lower carbon footprint vs. PET |

| Polyhydroxyalkanoates (PHA) | Marine biodegradable, good moisture barrier | Primary containers, caps | Home and industrial compostable |

| Bio-based PET | Identical to fossil PET, drop-in replacement | Bottles, vials | 20-30% carbon reduction |

| Cellulose-Based Films | Excellent oxygen barrier, renewable source | Blister lidding, pouches | Biodegradable, from sustainable forestry |

Advanced Recyclable and Monomaterial Systems

Designing for end-of-life recovery and circularity:

- High-Barrier Monolayer Films: PE and PP films with advanced coatings replacing multi-layer laminates.

- Design for Disassembly: Packaging components easily separable for recycling streams.

- Water-Soluble Polymers: PVOH-based systems dissolving in recycling processes.

- Compatible Material Families: Using single polymer families to enhance recyclability.

Sustainable Design Principles and Strategies

Innovative design approaches minimize material use while maintaining product protection and patient safety.

Lightweighting and Material Optimization

Systematic reduction of packaging material intensity:

- Thin-Wall Design: 20-40% material reduction in vials and primary containers.

- Structural Optimization: Computational design minimizing material while maintaining strength.

- Multi-Function Integration: Combining components to eliminate separate elements.

- Right-Sizing: Matching package dimensions precisely to product requirements.

Circular Economy Models and Reusable Systems

Transforming packaging from waste to resource:

- Refillable Primary Packaging : Durable containers designed for multiple use cycles.

- Take-Back Programs : Closed-loop recovery and recycling systems.

- Reusable Secondary Packaging : Returnable shippers and protective materials.

- Material Recovery Partnerships : Collaboration with waste management for dedicated streams.

Cold Chain Packaging Innovation

Sustainable solutions for temperature-controlled shipping present unique challenges and opportunities.

Insulation Material Alternatives

Replacing traditional expanded polystyrene (EPS) with sustainable options:

- Mushroom-Based Packaging : Mycelium-grown materials with excellent insulation properties.

- Recycled Textile Fill : Post-consumer fabric providing thermal protection.

- Phase Change Materials (PCMs) : Reusable gel packs with reduced material volume.

- Corrugated Insulation : Paper-based systems with recycled content and recyclability.

Cold Chain System Optimization

Holistic approaches to reducing environmental impact:

| Strategy | Implementation | Environmental Benefit | Cost Impact |

| Temperature Excursion Analytics | IoT sensors optimizing packaging performance | Reduced over-packaging | 20-30% savings |

| Regional Manufacturing | Reduced transportation distance and duration | Lower carbon emissions | Variable |

| Reusable Cold Chain Assets | Returnable shippers with 20+ use cycles | 85-90% waste reduction | 40-60% savings |

| Passive System Optimization | Advanced materials extending temperature control | Reduced refrigerant use | 15-25% savings |

Life Cycle Assessment and Environmental Impact Measurement

Quantitative assessment provides the foundation for informed sustainable packaging decisions.

Key Environmental Impact Metrics

Comprehensive measurement of packaging sustainability:

- Carbon Footprint: Greenhouse gas emissions throughout lifecycle (kg CO2e).

- Material Circularity: Percentage of recycled content and recyclability.

- Water Usage: Total water consumption in production and use.

- Waste Generation: Pre- and post-consumer waste streams.

Assessment Methodologies and Standards

International frameworks for environmental evaluation:

- ISO 14040/14044: Life Cycle Assessment (LCA) standards.

- Product Environmental Footprint (PEF): EU methodology for product impact.

- Circular Transition Indicators: WBCSD framework for circularity measurement.

- Environmental Product Declarations (EPDs): Third-party verified impact reports.

Regulatory Compliance and Quality Considerations

Sustainable packaging must meet stringent pharmaceutical requirements while reducing environmental impact.

Quality and Safety Requirements

Maintaining product integrity with sustainable materials:

- Extractables and Leachables: Comprehensive testing for novel materials.

- Barrier Properties: Demonstrated protection against moisture, oxygen, and light.

- Sterility Assurance : Compatibility with sterilization methods.

- Stability Data : Real-time studies confirming product protection.

Global Regulatory Landscape

International standards and evolving requirements:

- FDA Guidance: Container closure integrity for novel materials.

- EMA Requirements: Environmental risk assessment considerations.

- Pharmacopoeial Standards : USP, EP, JP compatibility testing.

- International Regulations : Regional packaging waste and recycling mandates.

Case Studies: Successful Sustainable Packaging Implementations

Leading peptide manufacturers demonstrate the feasibility and benefits of sustainable packaging innovation.

Case Study 1: Global Peptide Manufacturer

A major API producer implemented comprehensive sustainable packaging:

- Challenge: High carbon footprint from traditional glass vials and plastic components.

- Solution: Bio-based polymer vials with 40% recycled content, lightweight design.

- Results: 45% carbon reduction, 30% material savings, enhanced brand perception.

- Business Impact: $3.2 million annual savings, preferred supplier status with ESG-focused clients.

Case Study 2: Specialty Peptide CDMO

A contract manufacturer implemented circular packaging models:

- Challenge: Client demand for sustainable packaging solutions.

- Solution: Reusable cold chain shippers with take-back program.

- Results: 80% waste reduction, 50% cost savings for clients.

- Strategic Impact: Market differentiation and 25% new client growth from sustainability focus.

Future Trends and Innovations

The sustainable packaging landscape continues to evolve with emerging technologies and materials.

Advanced Materials and Technologies

Next-generation solutions enhancing sustainability:

- Nanocellulose Barriers : Ultra-thin, high-performance barriers from renewable sources.

- Smart Packaging : Integrated sensors for condition monitoring and waste reduction.

- Chemical Recycling : Advanced processes enabling true circularity for complex materials.

- Digital Watermarking : Enabling accurate sorting and increased recycling rates.

Regulatory and Market Evolution

Anticipated changes in the sustainability landscape:

- Extended Producer Responsibility : Expanding mandates and increased fees for non-recyclable packaging.

- Carbon Border Adjustments : Taxes on high-carbon packaging materials.

- Circity Requirements : Minimum recycled content mandates.

- Transparency Demands : Required disclosure of environmental impacts.

FAQs: Sustainable Peptide Packaging Innovation

Q: What are the most significant challenges in implementing sustainable packaging for peptide therapeutics, and how are companies overcoming them?

A: The most significant challenges include maintaining the stringent barrier properties required for peptide stability, ensuring compatibility with sterilization methods, navigating complex regulatory pathways for novel materials, and managing cost implications. Companies are overcoming these through several strategies: developing advanced bio-based materials with enhanced barrier properties through nanotechnology or coatings, conducting comprehensive extractables and leachables studies early in development, engaging regulatory agencies proactively through pre-submission meetings, and taking a total cost of ownership perspective that accounts for waste disposal fees, regulatory penalties, and brand value.

Successful implementations typically involve cross-functional teams combining packaging engineering, regulatory affairs, quality assurance, and sustainability expertise from the earliest stages of product development.

Q: How do the costs of sustainable packaging materials compare to traditional options, and what is the typical return on investment timeline?

A: Sustainable packaging materials typically have a 10-30% higher upfront cost compared to traditional options, but deliver significant savings throughout the product lifecycle. The ROI timeline is generally 1-3 years, with savings emerging from multiple areas: material reduction through lightweighting (10-25% savings), reduced waste disposal fees (20-40% savings), avoidance of extended producer responsibility fees (15-30% savings), and operational efficiencies. Additionally, sustainable packaging often qualifies for tax incentives and green financing with lower interest rates.

The most comprehensive analyses show total cost savings of 15-35% over traditional packaging when all factors are considered. Companies should conduct detailed lifecycle cost analyses that include direct material costs, waste management expenses, regulatory compliance costs, and potential revenue benefits from enhanced brand preference.

Q: What sustainable packaging options are available for peptide products requiring cold chain transportation, and how do they perform compared to traditional expanded polystyrene (EPS) containers?

A: Several sustainable alternatives to EPS now offer comparable or superior performance for cold chain peptide transportation. Mushroom-based packaging provides excellent insulation properties (comparable R-value to EPS), is home compostable, and has 90% lower carbon footprint. Recycled textile insulation offers thermal performance within 10-15% of EPS with 70% lower environmental impact. Reusable passive containers with phase change materials can achieve 96+ hour temperature stability with 80-90% waste reduction over their lifecycle.

Corrugated paper-based systems with recycled content provide good protection for shorter shipments with excellent recyclability. The key is matching the alternative to specific shipment requirements—duration, temperature range, and external conditions. Most alternatives now meet or exceed ISTA and ASTM testing standards for pharmaceutical distribution, with the added benefit of significantly reduced environmental impact.

Core Takeaways

- Strategic Imperative: Sustainable packaging is essential for regulatory compliance, cost management, and brand leadership in peptide therapeutics.

- Material Innovation: Bio-based polymers, advanced recyclables, and renewable materials enable significant environmental impact reduction.

- Design Optimization: Lightweighting, circular models, and system thinking deliver both environmental and economic benefits.

- Holistic Assessment: Life cycle thinking and total cost analysis reveal the true value of sustainable packaging.

- Future Readiness: Innovation in materials and systems positions companies for evolving regulations and market expectations.

Conclusion: The Future of Sustainable Peptide Packaging

Sustainable packaging innovation represents a transformative opportunity for the peptide therapeutics industry to align environmental responsibility with business excellence. As regulatory pressures intensify, patient preferences evolve, and material science advances, sustainable packaging will increasingly become a competitive differentiator and business imperative. Companies that lead in this transition will benefit from reduced costs, enhanced brand value, improved patient satisfaction, and stronger resilience against regulatory changes and resource constraints.

The future of peptide packaging lies in intelligent, circular systems that maintain the highest standards of product protection while minimizing environmental impact. Through continued innovation in materials, design, and business models, collaborative partnerships across the value chain, and commitment to measurable sustainability goals, the peptide industry can significantly reduce its environmental footprint. This journey promises not only environmental benefits but also economic advantages, creating shared value for patients, businesses, and the planet while supporting the essential role of peptide therapeutics in global healthcare.

Disclaimer:

This article contains information, data, and references that have been sourced from various publicly available resources on the internet. The purpose of this article is to provide educational and informational content. All trademarks, registered trademarks, product names, company names, or logos mentioned within this article are the property of their respective owners. The use of these names and logos is for identification purposes only and does not imply any endorsement or affiliation with the original holders of such marks. The author and publisher have made every effort to ensure the accuracy and reliability of the information provided.

However, no warranty or guarantee is given that the information is correct, complete, or up-to-date. The views expressed in this article are those of the author and do not necessarily reflect the views of any third-party sources cited.