The global peptide therapeutics industry, on a trajectory to exceed $75 billion in value, is confronting a hydrological reality: the synthesis of a single kilogram of peptide API can consume between 5,000 to 15,000 liters of high-purity water, generating wastewater streams laced with organic solvents, salts, and bioactive residues. In an era where 40% of pharmaceutical companies report operational water risks and investors are allocating over $30 trillion to ESG-mandated funds, proactive water stewardship has transitioned from an environmental footnote to a core strategic pillar for resilience and license to operate. This comprehensive analysis examines the sophisticated wastewater treatment and recycling technologies enabling peptide manufacturers to achieve 70-90% water reuse rates, reduce effluent discharge by 50-80%, and future-proof operations against escalating water scarcity, stringent regulations, and stakeholder demands for transparent, sustainable production practices.

The Water-Intensive Reality of Peptide Synthesis

Peptide manufacturing, particularly Solid-Phase Peptide Synthesis (SPPS), presents unique water challenges that extend far beyond simple consumption metrics.

The High-Cost Water Footprint of Peptide API Production

Key process stages driving water demand and waste generation:

- Solvent Use and Purification: Massive volumes of dimethylformamide (DMF), acetonitrile (ACN), and other solvents require water for dilution, quenching, and purification via reverse osmosis or distillation.

- Chromatography and Lyophilization: High-performance liquid chromatography (HPLC) for purification uses water as a mobile phase, while lyophilization (freeze-drying) consumes significant energy, often tied to water-cooled systems.

- Equipment and Facility Cleaning (CIP/SIP): Clean-in-Place and Steam-in-Place procedures in multi-product facilities generate large, variable effluent streams.

- Water for Injection (WFI) Generation: Producing USP-grade WFI via multi-effect or vapor compression distillation is highly energy and water intensive, with significant reject streams.

Characteristics and Challenges of Peptide Manufacturing Wastewater

Effluent is complex and difficult to treat:

- High Organic Load: Chemical Oxygen Demand (COD) levels can reach 10,000-50,000 mg/L from residual solvents, cleaving agents, and protecting groups.

- Salinity and Conductivity: High concentrations of salts (e.g., from TFA cleavage, ion-exchange steps) inhibit biological treatment and challenge membrane systems.

- Variable Composition: Batch processes lead to “shock loads” of different contaminants, requiring robust and flexible treatment systems.

- Potential Ecotoxicity: Residual peptides or active pharmaceutical ingredients (APIs) pose a risk to aquatic life, driving stringent pre-treatment requirements.

“Water is not just a utility in peptide manufacturing; it is a critical reagent, a cleaning agent, and our largest waste stream. True water stewardship isn’t about using less water—it’s about rethinking the entire molecule-water relationship, designing processes that recover, purify, and reuse every drop, turning a cost center into a circular resource.” — Dr. Aris Thoma, Global Head of Environmental Sustainability, Lonza.

Advanced Wastewater Treatment Technology Arsenal

Treating peptide wastewater requires a multi-barrier approach tailored to the specific contaminant profile.

Primary and Physicochemical Treatment

Initial removal of solids, oils, and solvent recovery:

| Technology | Primary Mechanism | Target Contaminants | Efficiency & Considerations |

|---|---|---|---|

| Solvent Recovery Distillation | Fractional distillation to separate and reclaim DMF, ACN, etc. | Bulk organic solvents | Can recover >95% of solvent, significantly reducing organic load and operating costs. High capital cost. |

| Coagulation/Flocculation | Addition of chemicals to destabilize and aggregate suspended/colloidal matter. | Fine particles, some organics | Reduces turbidity and some COD. Generates chemical sludge for disposal. |

| Dissolved Air Flotation (DAF) | Microbubbles attach to particles, floating them to the surface for removal. | Fats, oils, greases, precipitated organics. | Effective for pre-treatment before biological systems. |

Secondary Biological Treatment

Utilizing microorganisms to degrade soluble organic matter:

- Activated Sludge Process (ASP): The workhorse of biological treatment. Must be adapted to handle the inhibitory salinity and variable loads of peptide waste; often requires extended aeration.

- Moving Bed Biofilm Reactor (MBBR): Microbes grow on protected plastic carriers suspended in the tank. More resilient to shock loads and toxic compounds than conventional ASP.

- Membrane Bioreactor (MBR): Combines biological treatment with microfiltration or ultrafiltration membranes. Produces high-quality effluent suitable for direct reuse or advanced polishing. Key for footprint-limited sites.

- Anaerobic Digestion: For high-strength waste streams, anaerobic processes can convert organics to biogas (methane) for energy recovery, though sensitivity to salts and solvents requires careful acclimation.

Tertiary and Advanced Treatment for Reuse

Polishing effluent to high purity standards:

| Technology | Primary Mechanism | Target | Role in Water Stewardship |

|---|---|---|---|

| Advanced Oxidation Processes (AOPs) | Generation of hydroxyl radicals (•OH) to oxidize recalcitrant organics and trace APIs. | Micropollutants, color, residual COD | Critical for breaking down bioactive peptide residues and ensuring effluent safety. Methods: Ozone/UV, Fenton, photocatalysis. |

| Reverse Osmosis (RO) | Semi-permeable membrane removes ions, organics, and microbes. | Dissolved salts, final polishing | Produces high-purity permeate for reuse. Generates a concentrated brine stream (RO concentrate) that requires management. |

| Ion Exchange (IX) | Exchange of ions in solution with ions on a resin. | Specific ions (e.g., TFA counter-ions, ammonium) | Used for targeted removal of problematic ions or final polishing. Regeneration creates a small, concentrated waste stream. |

| Activated Carbon Adsorption (GAC/PAC) | Physical adsorption of organic molecules onto carbon surface. | Trace organics, color, odor | Polishing step post-biological treatment or as a safety barrier. Spent carbon requires regeneration or disposal. |

Integrated Water Recycling and Zero Liquid Discharge (ZLD) Strategies

The ultimate goal is closing the water loop within the manufacturing site.

Designing for Water Reuse: Quality Fit-for-Purpose

Not all processes need WFI. A cascading reuse strategy maximizes efficiency:

- High-Purity Reuse (RO Permeate): Treated to meet purified water or WFI standards for non-product contact cooling, boiler feedwater, or as feed to the WFI generation system.

- Medium-Purity Reuse (MBR/UF Effluent): Used for equipment washdown, floor cleaning, or landscaping irrigation.

- Process Integration: Using recycled water in early synthetic steps where purity requirements are lower, reserving fresh high-purity water for final purification and formulation.

The Zero Liquid Discharge (ZLD) Ambition

Eliminating liquid waste discharge by recovering both water and solids:

- Pre-concentration: Using high-efficiency RO or electrodialysis to maximize water recovery (up to 90-95%) and minimize brine volume.

- Brine Crystallization: Evaporating the remaining brine to dryness in a forced-circulation or falling-film crystallizer, producing a solid salt cake for disposal or potential recovery.

- Condensate Recovery: The distilled vapor from crystallizers is condensed, producing ultra-pure water that can be returned to the process.

- Drivers for ZLD: Geographically water-stressed locations, stringent local discharge regulations, or corporate sustainability commitments. High capital and operational energy costs are the primary barrier.

Monitoring, Compliance, and Stewardship Frameworks

Effective management requires data, clear standards, and integration into corporate governance.

Critical Water Quality Parameters and Monitoring

Essential analytics for process control and compliance:

- Influent/Effluent Characterization: COD/BOD, Total Dissolved Solids (TDS), Total Organic Carbon (TOC), specific ions (chloride, sulfate), pH, conductivity, toxicity (e.g., Microtox®).

- Online Sensors: For real-time control of treatment plants: pH, ORP (for AOPs), dissolved oxygen, turbidity, TOC analyzers.

- Micro pollutant Analysis: LC-MS/MS screening for specific peptide residues and transformation products to ensure complete removal.

Regulatory Compliance and Voluntary Standards

Navigating the compliance landscape:

- Local Discharge Permits: National Pollutant Discharge Elimination System (NPDES) in the US, Integrated Pollution Prevention and Control (IPPC) in the EU, setting limits on flow, COD, nutrients, and specific toxins.

- Industry Initiatives: The Pharmaceutical Supply Chain Initiative (PSCI) environmental expectations, and the Alliance for Water Stewardship (AWS) Standard.

- Certifications: ISO 14001 (Environmental Management) and ISO 46001 (Water Efficiency Management Systems) provide frameworks for continuous improvement.

- ESG Reporting: Disclosing water metrics (Water Use Efficiency, recycling rates, discharge quality) in frameworks like CDP Water Security and GRI 303.

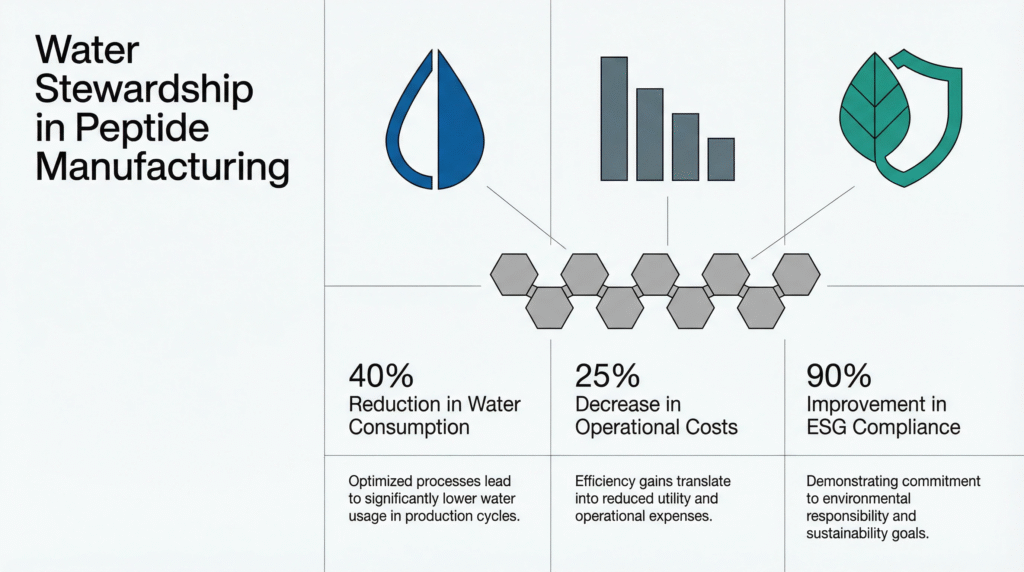

The Business Case: Cost, Risk, and Value

Investing in water stewardship delivers tangible financial and strategic returns.

Financial Analysis and ROI

| Cost/Saving Category | Description | Potential Impact |

|---|---|---|

| Capital Expenditure (CapEx) | Investment in treatment and recycling infrastructure. | High upfront cost, but decreasing with technology maturity and modular designs. |

| Operational Expenditure (OpEx) Reduction | Savings from reduced freshwater purchase, sewer discharge fees, and solvent recovery. | Can achieve 20-40% reduction in total water management costs. Solvent recovery often pays for itself. |

| Risk Mitigation Value | Avoided costs of regulatory fines, production stoppages due to water shortage, and reputational damage. | Difficult to quantify but often the primary driver for major investments. |

| Brand and Market Value | Enhanced reputation with ESG investors, large pharma customers seeking sustainable suppliers, and talent attraction. | Increasingly a condition for preferred supplier status and premium financing (green bonds). |

Future Trends and Innovation Horizon

The technology and regulatory landscape for water stewardship is rapidly evolving.

Emerging Treatment Technologies

- Electrochemical Processes: Electro-oxidation for on-site, chemical-free destruction of organics, and electrodialysis for selective salt removal.

- Forward Osmosis (FO): For concentrating high-salinity streams with lower fouling propensity and energy use than RO, often paired with a “draw solution” recovery system.

- Bioelectrochemical Systems: Microbial fuel cells that treat wastewater while generating a small electrical current, though currently at pilot scale.

- Digital Twins and AI Optimization: Real-time simulation of the treatment plant to optimize chemical dosing, energy use, and predict maintenance needs.

Systemic and Regulatory Shifts

- Water Positivity: Corporate goals moving beyond efficiency to net-positive water impact, replenishing stressed watersheds.

- Circular Economy Mandates: EU Circular Economy Action Plan and similar initiatives pushing for minimum recycled content and resource efficiency, indirectly driving water reuse.

- Increased API Residue Scrutiny: Regulators requiring Environmental Risk Assessments (ERAs) for new marketing authorizations, forcing earlier consideration of API removal during wastewater treatment.

FAQs: Peptide Manufacturing Water Stewardship

Q: What is the typical payback period for investing in a comprehensive water recycling system for a peptide manufacturing facility?

A: The payback period varies significantly based on scale, location, and local water/sewer costs, but typically ranges from 3 to 7 years. For a facility in a water-stressed region with high tariffs, payback can be at the shorter end of this range, driven by direct savings on water procurement and discharge fees. Systems that incorporate solvent recovery often have the fastest payback (1-3 years) due to the high value of reclaimed DMF or ACN. The business case strengthens when including avoided risks (drought-related shutdowns) and softer benefits like enhanced ESG ratings, which are increasingly critical for customer contracts and financing.

Q: Can biologically treated wastewater from peptide manufacturing truly be made safe enough to release into the environment, given the concern about active pharmaceutical ingredients (APIs)?

A: Conventional biological treatment alone is often insufficient to completely remove or degrade bioactive peptide residues, which is a major environmental concern. Ensuring safety requires a multi-barrier approach. This typically involves robust biological treatment (e.g., MBR) followed by an Advanced Oxidation Process (AOP) – such as ozone/UV or a catalytic wet peroxide oxidation – specifically designed to break down these complex organic molecules. The final effluent should be monitored using sensitive LC-MS/MS methods to confirm the absence of the parent compound and its major transformation products before discharge. This “treatment train” is now considered a best practice for API manufacturing sites.

Q: For a small to mid-sized peptide CDMO, what are the first, most impactful steps towards better water stewardship?

A: SMEs should start with a comprehensive water audit to establish a baseline: measure water consumption and wastewater generation at each major process step. The first impactful actions are often operational and low-capital: 1) Implement solvent recovery for DMF/ACN; it has a quick ROI. 2) Optimize CIP cycles to use less water and recover final rinses. 3) Explore segregating waste streams; keeping high-salinity streams separate can make treatment or evaporation more feasible. 4) Investigate partnerships: Sending concentrated waste to a specialized third-party treatment facility can be more economical than building on-site treatment. 5) Set clear reduction and reuse targets and engage staff in identifying savings. This builds a stewardship culture and creates a business case for future capital investments.

Core Takeaways

- Strategic Imperative, Not Just Compliance: Water stewardship is a critical business strategy for mitigating physical, regulatory, and reputational risk in the peptide industry, directly impacting resilience and social license to operate.

- Technology Integration is Key: No single technology solves the challenge. Effective treatment requires a tailored sequence (treatment train) combining physicochemical, biological, and advanced polishing technologies to handle complex, variable wastewater.

- Recycle and Reuse is the Goal: The highest form of stewardship is closing the water loop. A fit-for-purpose reuse strategy, cascading water from high-purity to lower-purity applications, dramatically reduces freshwater intake and wastewater discharge.

- Data-Driven Management: Continuous monitoring of key water quality parameters, coupled with clear governance frameworks (e.g., AWS Standard, ISO 46001), is essential for optimizing systems, ensuring compliance, and demonstrating performance.

- Strong Business Case: Investments in water efficiency and recycling yield direct operational savings, de-risk the supply chain, and enhance brand value with investors and customers, delivering a compelling return on investment.

Conclusion: Securing a Water-Secure Future for Peptide Innovation

The journey towards comprehensive water stewardship in peptide manufacturing is a complex but essential evolution, aligning ecological responsibility with long-term business viability. As water scarcity intensifies and regulatory pressures mount, the companies that lead in adopting and innovating advanced wastewater treatment and recycling technologies will secure a significant competitive advantage. They will build operations resilient to climate shocks, attract sustainability-focused capital and partnerships, and fulfill a fundamental duty to protect the shared water resources upon which communities and ecosystems depend.

This transition requires viewing water not as a limitless commodity to be consumed and discharged, but as a precious, circular resource within the manufacturing process. By embracing the principles of reduce, recover, reuse, and recycle, the peptide industry can ensure that its remarkable contributions to human health are not made at the expense of planetary health, paving the way for a truly sustainable model of biomedical innovation.

Disclaimer

This article contains information, data, and references that have been sourced from various publicly available resources on the internet. The purpose of this article is to provide educational and informational content. All trademarks, registered trademarks, product names, company names, or logos mentioned within this article are the property of their respective owners. The use of these names and logos is for identification purposes only and does not imply any endorsement or affiliation with the original holders of such marks. The author and publisher have made every effort to ensure the accuracy and reliability of the information provided. However, no warranty or guarantee is given that the information is correct, complete, or up-to-date. The views expressed in this article are those of the author and do not necessarily reflect the views of any third-party sources cited.