The biopharmaceutical industry stands at a critical juncture. While its mission is to heal, its manufacturing processes, particularly for complex molecules like peptide Active Pharmaceutical Ingredients (APIs), have historically carried a significant environmental burden. Among these, water consumption stands out as a critical sustainability challenge. Peptide synthesis, especially Solid-Phase Peptide Synthesis (SPPS), is notoriously solvent- and water-intensive, generating liters of waste per gram of final product. In an era of increasing water scarcity, stringent ESG (Environmental, Social, and Governance) reporting, and conscientious investor and consumer pressure, reducing the water footprint of peptide manufacturing is no longer just an environmental ideal—it is a strategic imperative for cost reduction, regulatory compliance, and corporate reputation. This article delves into the cutting-edge technologies and operational strategies that forward-thinking API manufacturers are deploying to minimize water use, transforming peptide production into a model of efficiency and environmental stewardship.

Understanding the Water Footprint in Peptide API Manufacturing

The water footprint extends beyond direct process water use (blue water) to include the water required to treat wastewater (grey water) and the virtual water embedded in solvents and raw materials. For peptides, the impact is concentrated in several key areas.

Where Does the Water Go? A Process Breakdown

- Reaction & Coupling Solvents: SPPS relies heavily on polar aprotic solvents like DMF (N,N-Dimethylformamide) and NMP (N-Methyl-2-pyrrolidone). While not water themselves, their production is water-intensive, and they generate wastewater that requires significant water for dilution and treatment.

- Washing Steps: After each coupling and deprotection cycle, the resin-bound peptide is washed multiple times (typically 3-5 washes) with DMF, DCM, or other solvents to remove excess reagents. This is the single largest contributor to solvent and subsequent wastewater volume.

- Cleavage & Precipitation: The final cleavage from the resin and subsequent precipitation of the crude peptide into cold ether or water generates a mixed aqueous-organic waste stream that is challenging and water-intensive to treat.

- Purification (HPLC): Preparative HPLC, the gold standard for peptide purification, uses vast quantities of high-purity water and acetonitrile to form the mobile phase. A single run can consume hundreds of liters. The subsequent fraction pooling and solvent removal add to the water load.

- Lyophilization (Freeze-Drying): While not a direct consumer, the process relies on condensers cooled by water or uses energy from water-intensive sources.

- Cleaning Validation (CIP): Cleaning-In-Place (CIP) procedures for multi-product facilities require extensive rinsing with Water for Injection (WFI), a highly purified and energy/water-intensive commodity to produce.

The Business and Regulatory Driver for Water Stewardship

Beyond environmental ethics, compelling business drivers are accelerating adoption.

| Driver | Impact on Peptide API Manufacturers |

|---|---|

| Operational Cost Savings | Reducing solvent and water use directly lowers raw material purchase and waste disposal costs, which can constitute 20-40% of COGS. Efficient purification cuts energy costs. |

| Supply Chain Resilience | Manufacturing sites in water-stressed regions face operational risks. Reducing dependence on large, reliable water sources mitigates this risk. |

| Regulatory & Compliance Pressures | Environmental Protection Agency (EPA) and similar global bodies are tightening effluent guidelines. The EU’s Green Deal and sustainable finance taxonomy increasingly tie market access to environmental performance. |

| Investor & Customer Demand | ESG ratings from agencies like MSCI and Sustainalytics influence investment. Pharmaceutical clients (Big Pharma) increasingly demand sustainable sourcing as part of their Scope 3 emissions reporting. |

| License to Operate | Demonstrating environmental leadership builds trust with local communities and regulators, facilitating site expansions and approvals. |

“The conversation in boardrooms has shifted. We’re no longer just asking ‘Can we make this peptide?’ but ‘At what environmental cost?’ The water footprint is a direct line to both operational efficiency and social license. A sustainable process is, by definition, a more robust and future-proof one.” — Dr. Elena Rodriguez, VP of Sustainability, Global Pharma Solutions.

Core Technology Levers for Reducing Water Consumption

Innovation across the peptide synthesis and purification workflow is delivering dramatic reductions in water use.

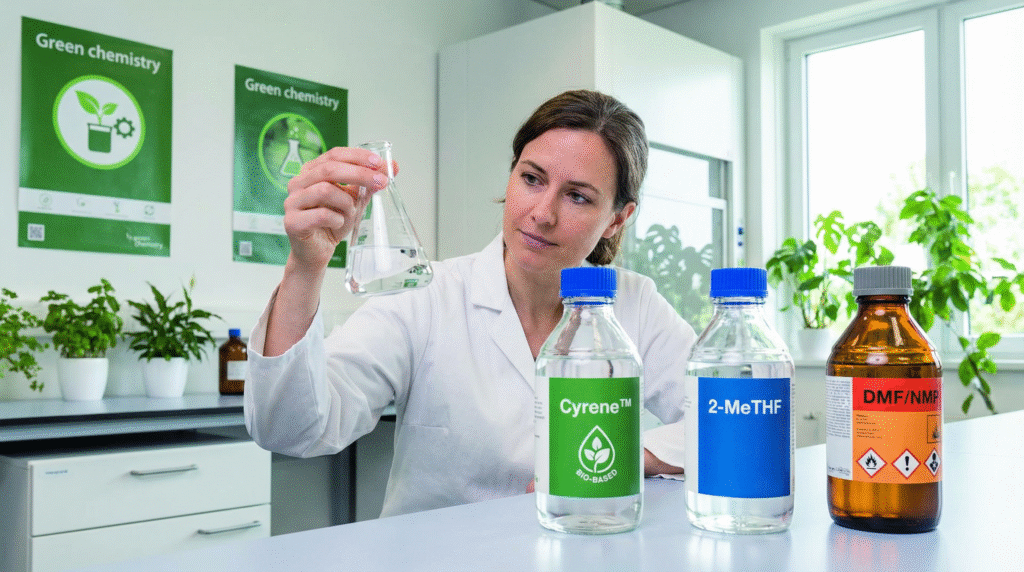

1. Green Chemistry & Alternative Solvent Systems

Re-engineering the core synthesis chemistry offers the most significant leverage.

- Moving Beyond DMF/NMP: Research into alternative, more environmentally benign solvents like Cyrene™ (dihydrolevoglucosenone), 2-MeTHF, or even switchable aqueous systems can drastically reduce toxicity and improve biodegradability, simplifying wastewater treatment and reducing its water footprint.

- Water as a Solvent for Specific Steps: For certain amino acids and coupling reactions, water-based or water-miscible systems are being explored, particularly for fragment condensation or in liquid-phase peptide synthesis, eliminating organic waste streams entirely for those steps.

- Enhanced Coupling Reagents: Developing more efficient coupling agents that work with higher fidelity at lower concentrations can reduce the excess required, thereby decreasing the volume of solvent needed for washing.

2. Process Intensification & Continuous Manufacturing

Moving from batch to more efficient processing models.

- Continuous Flow Peptide Synthesis (CFPS): In continuous flow, reagents are pumped through a reactor containing immobilized resin or in a homogeneous solution. This enables:

- Radical Solvent Reduction: Precise reagent mixing and immediate removal of by-products drastically cut wash volumes by up to 90%.

- Smaller Equipment Footprint: Reduced reactor size translates to smaller CIP volumes.

- Improved Purity: Often yields crude peptide of higher purity, reducing the burden on downstream purification.

- Automated, Optimized SPPS Platforms: Next-generation synthesizers with “low-wash” protocols, using just-in-time reagent delivery and optimized wash cycles based on real-time monitoring, can significantly cut standard wash volumes without compromising purity.

3. Revolutionizing Purification: Beyond Traditional Prep-HPLC

Purification is the most water- and solvent-intensive unit operation. Alternatives and optimizations are key.

| Technology | Mechanism for Water Reduction | Application Stage |

|---|---|---|

| Counter-Current Chromatography (CCC) | A liquid-liquid separation technique that uses no solid stationary phase, eliminating the need for silica-based columns and the associated solvent conditioning. It can use greener solvent systems and often requires less solvent overall. | Purification of crude peptide, especially for longer or more complex sequences where HPLC resolution is challenging. |

| Membrane-Based Separations (UF/NF) | Ultrafiltration (UF) and Nanofiltration (NF) membranes can be used for desalting, buffer exchange, and concentration of peptide solutions, replacing diafiltration steps that use large volumes of water. | Post-cleavage workup, buffer exchange before final purification, and solvent recovery. |

| Simulated Moving Bed (SMB) Chromatography | A continuous chromatographic process that significantly improves solvent efficiency and product concentration compared to batch HPLC, reducing mobile phase consumption per gram of pure product. | Large-scale, commercial purification of a single peptide. |

| Optimized Gradient HPLC Methods | Method development focused on “green chromatography”: using shorter columns, higher temperatures, alternative modifiers (e.g., ethanol instead of acetonitrile where possible), and steeper gradients to cut run time and solvent use. | Improving existing HPLC processes for all peptide purification stages. |

4. Advanced Wastewater Treatment & Solvent Recovery

Treating and reusing water closes the loop.

- On-Site Solvent Recovery Distillation: Installing distillation units to recover and purify high-value solvents like DMF, ACN, and DCM from waste streams. This reduces virgin solvent purchase and the water footprint of solvent production.

- Advanced Oxidation Processes (AOPs): Using ozone, UV/peroxide, or electrochemical methods to break down persistent organic compounds in wastewater, enabling higher quality water reuse for non-critical applications (e.g., cooling, initial rinsing).

- Biological Treatment Optimization: Tailoring bioreactors to handle high-nitrogen waste streams from peptide synthesis (from deprotected amines), improving efficiency and reducing the water needed for dilution to meet discharge limits.

Implementation Strategies: A Roadmap for API Manufacturers

Adopting these technologies requires a strategic, phased approach.

- Conduct a Water Footprint Audit: Map the entire manufacturing process to quantify water use (direct and virtual) at each unit operation. Use metrics like “Liters of water per gram of pure peptide API.” This baseline is critical for prioritizing efforts.

- Prioritize “Quick Wins”:

- Optimize Wash Cycles: Challenge standard protocols. Can wash volumes or counts be reduced without impacting quality? Implement a QbD approach to define the design space.

- Implement Solvent Recycling: Start with dedicated recovery loops for high-volume, high-cost solvents like DMF from the washing steps.

- Rainwater Harvesting & Greywater Reuse: Use collected rainwater or treated greywater for cooling towers or landscape irrigation.

- Invest in Pilot-Scale Innovation: Partner with equipment vendors or academic institutions to pilot disruptive technologies like Continuous Flow Synthesis or CCC for your most water-intensive products. Start with non-GMP material to de-risk.

- Design Sustainability into New Facilities & Processes: For new product introductions or facility expansions, mandate green chemistry and water-minimizing technologies from the start. It is far more cost-effective than retrofitting.

- Foster a Culture of Water Stewardship: Engage operators and scientists in identifying waste and ideating solutions. Tie environmental metrics to performance goals.

The Strategic Partner Advantage: How Your Peptide API Supplier Drives Your ESG Goals

Your supply chain is an extension of your environmental footprint. Choosing a peptide API manufacturer committed to sustainable practices directly reduces your Scope 3 emissions and advances your corporate sustainability goals. A partner like Sichuan Pengting Technology Co., Ltd. embeds water stewardship into its operational DNA, offering tangible value:

- Process Optimization from Molecule Design: Our chemists consider green chemistry principles during early development, selecting synthetic routes and protecting groups that minimize solvent use and waste generation from the outset.

- Investment in State-of-the-Art Infrastructure: Commitment to technologies like closed-loop solvent recovery systems, advanced wastewater pretreatment plants, and high-efficiency, low-wash peptide synthesizers to minimize freshwater intake.

- Purification Expertise: Expertise in developing and implementing purification strategies that balance yield and purity with environmental impact, leveraging techniques like optimized gradient HPLC and evaluating alternative methods for suitable projects.

- Transparent Environmental Reporting: Providing customers with key environmental metrics (e.g., Process Mass Intensity, water consumption per kg API) for their specific product, enabling accurate Scope 3 reporting and demonstrating a shared commitment to sustainability.

- Lifecycle Perspective: Understanding that sustainability extends beyond our factory gate, we collaborate on packaging optimization and logistics to reduce the total environmental footprint of the supplied API.

The Future: Towards Water-Positive Peptide Manufacturing

The trajectory points beyond reduction to regeneration and positive impact.

- AI-Powered Process Optimization: Machine learning algorithms will model synthesis and purification processes to identify the absolute minimum solvent and water requirements while guaranteeing quality, moving from experience-based to predictive minimization.

- Fully Integrated Water Recycle & Reuse: Factories will move towards “Zero Liquid Discharge” (ZLD) or near-ZLD systems, where all wastewater is treated and purified to a grade suitable for re-use in the process itself, effectively creating a closed-loop water system.

- Biocatalytic & Enzymatic Synthesis: The ultimate green chemistry: using engineered enzymes to assemble peptides in aqueous buffers at ambient temperatures, potentially eliminating organic solvents and their associated water footprint entirely for certain sequences.

FAQs: Water Footprint Reduction in Peptide API Manufacturing

Q: What is a realistic target for water reduction in peptide manufacturing, and how do we benchmark our performance?

A: A 30-50% reduction in process water intensity (L water/kg API) over 5-10 years is an ambitious but achievable target for manufacturers starting from a conventional baseline. Benchmarking is challenging due to molecule-specific complexity, but industry consortia are developing standardized metrics. Internally, track your Process Mass Intensity (PMI), which includes water and all materials per kg of API. Externally, you can use guidelines from the American Chemical Society Green Chemistry Institute Pharmaceutical Roundtable or the Together for Sustainability (TfS) initiative. The key is consistent measurement against your own baseline first.

Q: Does implementing water reduction technologies like continuous flow or solvent recovery have a positive return on investment (ROI)?

A: Yes, absolutely, though the payback period varies. The business case is strong:

1. Direct Cost Savings: Reduced purchase of virgin solvents (often the largest cost item after amino acids) and lower waste disposal costs. A solvent recovery unit can pay for itself in 1-3 years.

2. Operational Efficiency: Continuous processing often leads to higher productivity (more kg/day) from a smaller physical footprint.

3. Risk Mitigation: Protection against future water scarcity, rising solvent costs, and stricter environmental fines.

4. Market Access & Premium: Increasingly, sustainable manufacturing is a qualifier for partnerships with large pharma companies, who are willing to pay a “green premium” for a lower Scope 3 footprint.

Q: We are a small biotech developing a peptide therapeutic. How can we influence our CDMO’s approach to sustainable manufacturing and water use?

A: As a client, you have significant leverage. Sustainability should be a key criterion in your CDMO selection process and a defined element of your quality and supply agreements.

1. Ask the Right Questions: During vendor audits, inquire about their water footprint, solvent recovery rates, waste treatment protocols, and any green chemistry initiatives. Ask for specific data.

2. Co-Develop with Sustainability in Mind: From the start, discuss with your CDMO’s process development team the desire to optimize for environmental performance alongside yield and purity. Partners like Sichuan Pengting Technology Co., Ltd., who prioritize this, will offer greener alternative routes or purification strategies.

3. Include Sustainability in Contracts: Define expectations for reporting environmental metrics associated with your product’s manufacturing. This aligns incentives and makes sustainability a shared, measurable goal.

Core Takeaways

- Water stewardship is a strategic, not just environmental, necessity for peptide API manufacturers, driven by cost, regulation, and customer demand.

- The largest water footprint is often indirect, embedded in solvent use and wastewater treatment, not just in direct process water.

- A multi-pronged technological approach is required: Green chemistry, process intensification (continuous flow), innovative purification (CCC, membranes), and advanced solvent recovery/waste treatment.

- Implementation requires a strategic roadmap starting with an audit, prioritizing quick wins, and investing in pilot-scale innovation for disruptive technologies.

- Your API supplier’s sustainability performance is your Scope 3 footprint. Choosing a partner committed to water reduction, like Sichuan Pengting Technology, is a direct and powerful lever to advance your own corporate ESG goals and build a more resilient, responsible supply chain.

Conclusion: Securing the Future by Conserving Our Most Vital Resource

Reducing the water footprint of peptide API manufacturing is a complex but solvable challenge that sits at the intersection of green chemistry, advanced engineering, and operational excellence. The technologies and strategies exist today to make substantial improvements, turning an environmental liability into a source of efficiency, resilience, and competitive advantage. The journey requires investment, innovation, and collaboration across the value chain.

Success in this endeavor hinges on partnership. It requires API manufacturers who view sustainability as core to their mission, not an add-on. Sichuan Pengting Technology Co., Ltd. is committed to being that partner. As a professional and reliable peptide API supplier, we are investing in the infrastructure, expertise, and green chemistry principles that minimize the environmental impact of our production. We understand that providing a high-quality peptide also means providing it responsibly, with full transparency into the resources consumed in its creation. By partnering with us, you secure not only a supply of critical therapeutic ingredients but also a tangible contribution to your sustainability targets, helping to ensure that the business of healing does not come at the expense of the planet’s health.

Disclaimer

This article contains information, data, and references that have been sourced from various publicly available resources on the internet. The purpose of this article is to provide educational and informational content. All trademarks, registered trademarks, product names, company names, or logos mentioned within this article are the property of their respective owners. The use of these names and logos is for identification purposes only and does not imply any endorsement or affiliation with the original holders of such marks. The author and publisher have made every effort to ensure the accuracy and reliability of the information provided. However, no warranty or guarantee is given that the information is correct, complete, or up-to-date. The views expressed in this article are those of the author and do not necessarily reflect the views of any third-party sources cited.