The global peptide API market, projected to reach $75 billion by 2028, is built upon a foundation of complex, multi-step syntheses where a single impurity introduced early can propagate catastrophically, compromising the safety and efficacy of the final therapeutic. The strategic definition and rigorous qualification of Regulatory Starting Materials (RSMs) is the critical first control point in this journey, yet it remains a primary source of regulatory divergence and delay, with over 30% of chemistry, manufacturing, and controls (CMC) deficiencies cited by agencies relating to starting material justification.

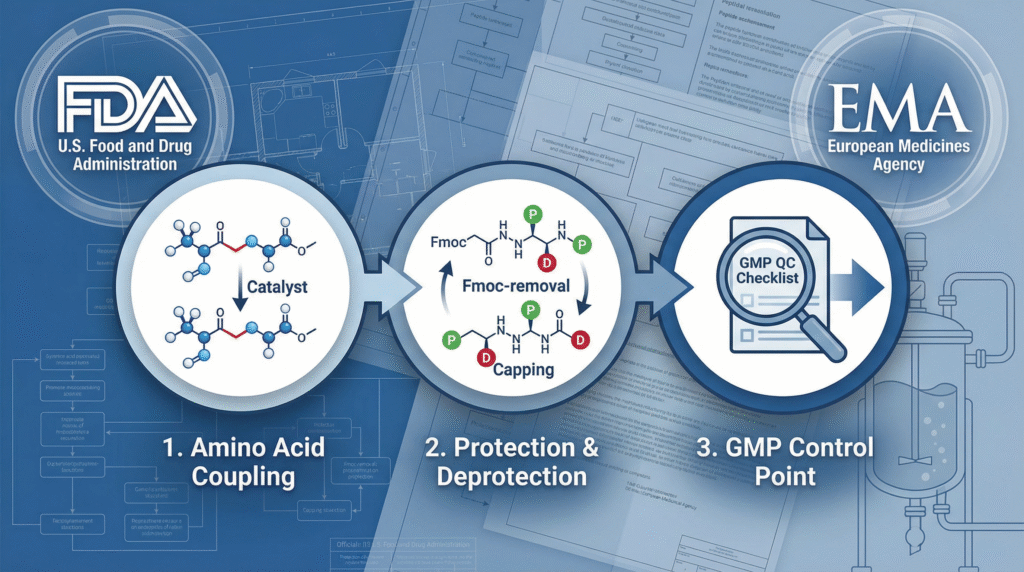

This definitive guide dissects the nuanced expectations of the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA), providing a clear, actionable framework for defining, qualifying, and documenting peptide RSMs to streamline regulatory submissions, ensure supply chain robustness, and build a defensible quality foundation for your peptide drug substance.

The High Stakes of Starting Material Definition: More Than an Academic Exercise

In peptide synthesis, the point at which you begin to impose GMP controls determines the scope of your regulatory responsibility, manufacturing cost, and supply chain risk.

Why the RSM Decision is a Strategic Business Choice

The definition of an RSM has cascading implications:

- Scope of GMP Application: All steps from the RSM onward must be performed under cGMP (ICH Q7). Defining an RSM too late expands GMP scope and cost unnecessarily; defining it too early increases supply chain vulnerability.

- Depth of Regulatory Review: The chemistry and controls for steps prior to the RSM are described succinctly. Steps after the RSM are subject to intense scrutiny, including process validation and impurity fate mapping.

- Supply Chain Control & Flexibility: RSMs are typically the point where a change of supplier constitutes a major variation requiring regulatory approval. A well-chosen RSM provides a logical point of control over a complex supply chain.

- Intellectual Property Protection: The synthetic route up to the RSM can be kept as a trade secret, while steps afterward are detailed in the open part of the dossier.

The Core Regulatory Principle: The “Significant Structural Fragment” Test

Both FDA and EMA fundamentally ask: Is the proposed starting material a significant structural fragment of the drug substance?

- A “Yes” means the material is plausibly an RSM candidate, subject to further justification.

- A “No” means the material is too far removed in structure and is considered an intermediate, requiring full GMP controls and detailed reporting.

- For peptides, this often centers on whether the proposed RSM is an amino acid, a protected amino acid, or a short peptide fragment that is clearly recognizable within the final sequence.

“The starting material is the foundation upon which the quality of your drug substance is built. If the foundation is poorly characterized or unstable, the entire structure is at risk. A well-justified RSM strategy is not about regulatory minimalism; it’s about intelligent risk management, focusing your controls where they matter most for patient safety.” — Dr. Anya Sharma, Former FDA CMC Review Division Director.

Deciphering FDA Expectations: A Risk-Based, Science-First Approach

The FDA’s guidance is principle-based, emphasizing a scientific and risk-informed justification.

Key FDA Guidance and Policy Documents

- FDA Guidance for Industry: Drug Substance Chemistry, Manufacturing, and Controls Information (January 2010): The primary document outlining RSM principles.

- ICH Q11: Development and Manufacture of Drug Substances: The international harmonized guideline adopted by the FDA, providing the global standard for RSM selection and justification.

- Risk-Based Approach: The FDA expects justification to focus on the potential of impurities formed in steps prior to the RSM to carry through, react, or form new impurities that impact the safety of the Drug Substance.

FDA’s Six Criteria for RSM Justification (Per ICH Q11)

A proposed starting material must be justified against these criteria:

- Manufacturer’s Responsibility: The drug substance manufacturer (the applicant) must assume responsibility for the quality of the RSM as if they had performed the steps themselves.

- Structural Similarity: The RSM should be a significant structural fragment. For a peptide, this is typically satisfied by a single amino acid or a di-/tri-peptide that is incorporated directly.

- Commercial Availability: The RSM should be a item of commerce, with multiple suppliers, to ensure supply continuity. This is a point of debate for specialized, protected amino acids.

- Robust Control: Impurities present in or formed prior to the RSM can be adequately controlled in the RSM specification or demonstrated to be purged in subsequent steps.

- Chemical Transformation: The chemical transformations between the RSM and the drug substance are well understood. For SPPS, the coupling, deprotection, and cleavage steps are considered well-understood.

- Risk Level: The level of GMP applied should be commensurate with the risk posed by the RSM, considering its complexity, impurity profile, and the number of steps to the DS.

Common FDA Pitfalls for Peptide Companies

- Over-Aggressive RSM Selection: Proposing a complex, multi-ton Boc-protected peptide fragment as an RSM without a compelling justification for its control.

- Inadequate Impurity Purging Justification: Failing to provide data (e.g., from development or spiking studies) showing that impurities from the RSM or earlier steps are removed to acceptable levels.

- Weak Supplier Control Argument: For a sole-source, custom-synthesized “RSM,” failing to demonstrate why the step producing it cannot be brought under the applicant’s GMP control.

Navigating EMA Expectations: A Stricter, More Prescriptive Path

The EMA, through its CHMP/CVMP/QWP/CPWP guideline, often takes a more restrictive view, especially for biological/biotechnological processes, which can influence peptide assessment.

Key EMA Guideline

- Guideline on the requirements for the chemical and pharmaceutical quality documentation concerning investigational medicinal products in clinical trials (CHMP/QWP/185401/2011) and the more general principles in ICH Q11, as interpreted by the EU.

- Biological Peptide Interpretation: For recombinant peptides or longer, more complex peptides, the EMA may consider the entire fermentation or expression process as part of the drug substance manufacture, pushing the RSM definition back to the gene or cell bank.

- Heightened Scrutiny for “Non-Traditional” RSMs: The EMA is generally less accepting of very short peptide fragments (e.g., di-peptides) as RSMs for longer chains, often expecting the RSM to be a single amino acid.

Notable Differences from FDA Stance

| Aspect | FDA Typical Stance | EMA Typical Stance |

|---|---|---|

| Acceptable RSM Complexity | More open to di-/tri-peptides as RSMs with strong justification on impurity control. | Prefers single amino acids. Views peptide fragments as “intermediates” requiring full GMP. |

| Commercial Availability Argument | Considered, but a custom-synthesized material can be an RSM if justified. | Places greater weight on this. A material made by a single, captive supplier is less likely to be accepted as an RSM. |

| Formal RSM Designation Process | Justification provided in Module 3 (Quality) of the dossier. | Strongly recommends (or requires for certain products) a formal “RSM Designation Request” via a Scientific Advice procedure prior to MAA submission. |

A Practical Framework for Defining and Justifying Peptide RSMs

A proactive, data-driven approach is essential for success with both agencies.

Step 1: Early Strategy and Target Profile Definition

- At the pre-IND/pre-IMPD stage, define a target RSM strategy aligned with your intended global markets (US vs. EU).

- For a global program, design for the stricter agency (often EMA) to avoid dual strategies.

- Engage with suppliers early to understand their capability to provide necessary quality and regulatory data (Type II DMF, CEP, Written Confirmation).

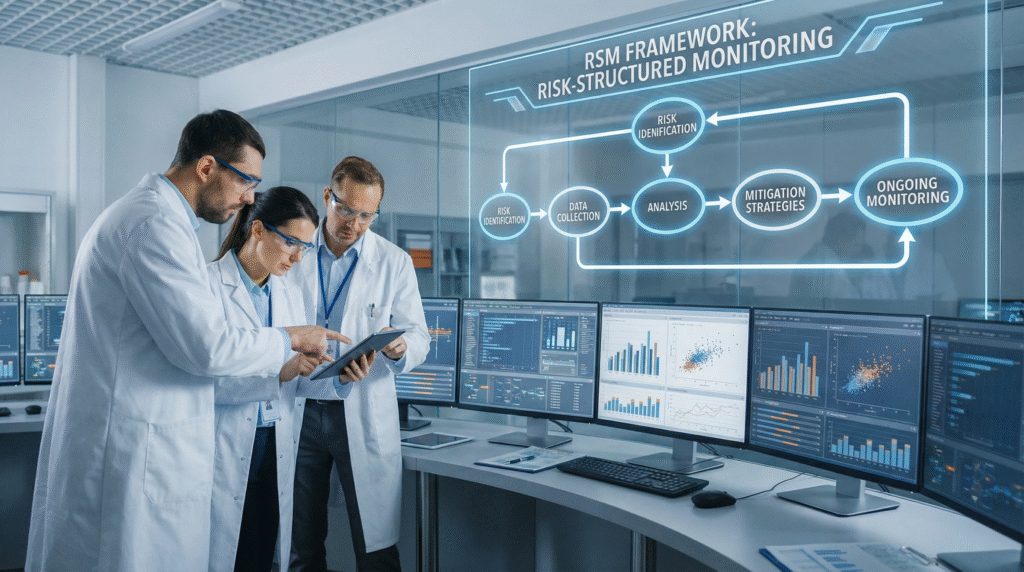

Step 2: Conduct a Comprehensive Risk Assessment

This is the core of the justification dossier:

- Identify Potential Impurities: From the proposed RSM and steps prior (e.g., isomers, deletion sequences, environmental contaminants from its synthesis).

- Assess Criticality: Which impurities are most likely to carry through, react, or form new impurities (e.g., potential for diketopiperazine formation)?

- Purging Studies: Design and execute controlled spiking studies to demonstrate that identified high-risk impurities are effectively removed (e.g., > 90-95% purge) during subsequent peptide synthesis and purification steps.

- Justify Specifications: Based on the risk assessment, set appropriate RSM specifications that control meaningful impurities. A simple identity/assay/purity test may be insufficient.

Step 3: Build the Justification Dossier

This becomes a section in Module 3.2.S.2 (Manufacture) of the Common Technical Document (CTD). It should include:

- A clear flow diagram highlighting the proposed RSM(s).

- A point-by-point justification against the ICH Q11 criteria.

- Summary of the risk assessment and purging study data.

- The RSM specification with rationale for each test and limit.

- Information on the RSM manufacturer and a commitment to audit them.

Special Considerations for Peptide Synthesis

Peptide chemistry introduces unique factors into the RSM discussion.

Synthetic Peptides (SPPS/LPPS)

- Protected Amino Acids as RSMs (e.g., Fmoc-AA-OH): Widely accepted by both agencies as they are clear structural fragments, commercially available, and the subsequent coupling/deprotection is well-understood. The main challenge is controlling enantiomeric purity and related amino acid impurities.

- Short Peptide Fragments (e.g., Di-peptides): A gray area. Strong justification required, focusing on the fragment being a recognizable “building block,” the commercial availability of multiple synthetic routes, and robust control of sequence-related impurities.

Recombinant Peptides

- The RSM is typically pushed back to the Master Cell Bank (MCB) or the gene construct. The fermentation harvest is considered the first step of drug substance manufacture.

- The definition of the “Drug Substance” often starts at the purified bulk peptide after the initial capture and purification from the fermentation broth.

Proactive Regulatory Engagement: Scientific Advice and QbD

Don’t wait for the review to discover a problem.

Formal Regulatory Interactions

- FDA INTERACT or Type C Meetings (Pre-IND/IND stage): Highly recommended to discuss and align on the proposed RSM strategy, especially for novel or complex peptides.

- EMA Scientific Advice: Almost essential for EU-focused programs. The procedure allows for a formal question on RSM designation and provides binding feedback from the Committee for Medicinal Products for Human Use (CHMP).

Quality by Design (QbD) as a Justification Tool

Implementing QbD principles strengthens your RSM position:

- Defining the Quality Target Product Profile (QTPP) and linking Critical Quality Attributes (CQAs) of the drug substance back to potential RSM impurities.

- Using the knowledge from your risk assessment to define a control strategy for the RSM that is science-based, not just compliance-based.

Future Trends and Evolving Scrutiny

The regulatory landscape for starting materials is not static.

Increasing Focus on Supply Chain Transparency and Sustainability

- Forced Labor & ESG: Expectations for deeper knowledge of the RSM supply chain, including origin of raw materials.

- Continuous Manufacturing: As peptide synthesis moves towards flow chemistry, the definition of an “intermediate” may change, potentially allowing for later RSM points with real-time analytics providing control.

Advanced Analytical and Digital Tools

- AI/ML for Impurity Prediction: Using models to predict potential genotoxic or persistent impurities from the RSM synthesis, strengthening the risk assessment.

- Digital Submissions: The eCTD and future ISO IDMP standards will make it easier for regulators to analyze and compare RSM justifications across applications, potentially increasing consistency of reviews.

FAQs: Peptide Starting Material Qualification

Q: For a generic peptide drug (a generic of an already approved product), can I simply copy the RSM defined in the Reference Listed Drug’s (RLD’s) application?

A: Not blindly. While you should analyze the RLD’s patent and published information, you are responsible for your own justification. The regulatory standard (ICH Q11) applies equally. You must qualify your own RSM suppliers and provide current data. Furthermore, the originator’s RSM strategy may have been accepted under older guidelines or as part of a specific negotiation.

Your generic application will be assessed against current expectations. It is a best practice to reverse-engineer the likely RSM from public data but then build your own, modern justification for it, potentially using a more robust analytical method for impurity control than was available when the originator filed.

Q: How much GMP is required for the manufacturing site producing the RSM? Does it need to be fully ICH Q7 compliant?

A: The FDA and EMA expect that the RSM manufacturer operates under a quality system that is equivalent to ICH Q7 for the manufacturing steps they perform. This is a critical point. A full GMP certificate may not be required for early chemical steps, but the principles of quality management, equipment qualification, change control, and documentation must be in place.

The drug substance manufacturer (you) is responsible for auditing the RSM manufacturer to ensure this equivalence. The expectation increases with the complexity and risk associated with the RSM. A simple, well-understood amino acid from a major manufacturer requires less scrutiny than a custom-synthesized, complex peptide fragment.

Q: What happens if the agency disagrees with our proposed RSM during the review of our marketing application?

A: This is a major deficiency that can lead to a Complete Response Letter (FDA) or a Day 120 List of Questions (EMA). The agency will state that the proposed RSM is not adequately justified and is considered an intermediate. The remedy is costly and time-consuming: you must provide full details (process description, controls, validation) for all steps back to the agency-accepted RSM. This may involve qualifying a new, earlier RSM supplier, generating new stability data, and potentially re-running validation batches. This scenario underscores the critical importance of early strategy and proactive regulatory engagement via scientific advice.

Core Takeaways

- Proactive Justification is Mandatory: Simply declaring a material as an RSM is insufficient. A rigorous, scientific justification against ICH Q11 criteria, centered on impurity risk assessment, is required by both FDA and EMA.

- EMA is Often Stricter: For a global peptide program, assume the EMA’s more restrictive interpretation (preferring single amino acids) as your baseline to avoid developing dual strategies.

- Data is Your Best Argument: Impurity spiking and purging studies are the most powerful tools to justify that controls at the RSM, combined with the known purging capability of subsequent steps, ensure drug substance quality.

- Engage Early, Engage Often: Utilize FDA and EMA scientific advice procedures to gain alignment on your RSM strategy before major investment in process validation and dossier writing. This is a high-value investment.

- Think Beyond Compliance: A well-chosen and justified RSM strategy is a foundation for supply chain security, manufacturing flexibility, and robust, scalable quality—it is a core business strategy, not just a regulatory checkbox.

Conclusion: Building a Defensible Foundation for Peptide Quality

The qualification of Regulatory Starting Materials is a fundamental exercise in applied quality risk management that defines the boundary of GMP responsibility for a peptide drug substance. In an industry where regulatory expectations are precise and the cost of failure is monumental, a sophisticated, data-driven approach to RSM justification is non-negotiable. By understanding the nuanced perspectives of the FDA and EMA, conducting thorough scientific risk assessments, and engaging regulators proactively, peptide developers can transform this complex regulatory challenge into a strategic advantage. A robust RSM strategy secures a smoother regulatory pathway, a more resilient and controllable supply chain, and ultimately, a stronger foundation of quality for the innovative therapies delivered to patients.

Disclaimer

This article contains information, data, and references that have been sourced from various publicly available resources on the internet. The purpose of this article is to provide educational and informational content. All trademarks, registered trademarks, product names, company names, or logos mentioned within this article are the property of their respective owners. The use of these names and logos is for identification purposes only and does not imply any endorsement or affiliation with the original holders of such marks. The author and publisher have made every effort to ensure the accuracy and reliability of the information provided.

However, no warranty or guarantee is given that the information is correct, complete, or up-to-date. The views expressed in this article are those of the author and do not necessarily reflect the views of any third-party sources cited.